Cultivated meat could soon be on your plate - and at an affordable price. Bühler, a global leader in food processing, and Ever After Foods, an Israeli food tech company, have partnered to tackle the high costs and inefficiencies in cultivated meat production. Their collaboration introduces Ever After Foods' edible packed-bed (EPB) technology, which dramatically reduces production costs and space requirements.

Key Takeaways:

- Cost Reduction: Growth media consumption cut by over 90%, making cultivated meat cheaper.

- Efficiency: EPB technology uses 60x less volume and 10x smaller facilities than current methods.

- Product Quality: Produces structured meat (muscle, fat, and connective tissue) for beef, chicken, fish, and more.

- Timeline: Cultivated meat could hit UK shelves by 2027, pending regulatory approval.

This partnership could make cultivated meat a practical, affordable option for consumers, helping to meet growing protein demand while addressing production challenges.

The future of meat? Inside the Oxford-based startup turning cells into 'steaks'

Ever After Foods' Technology Explained

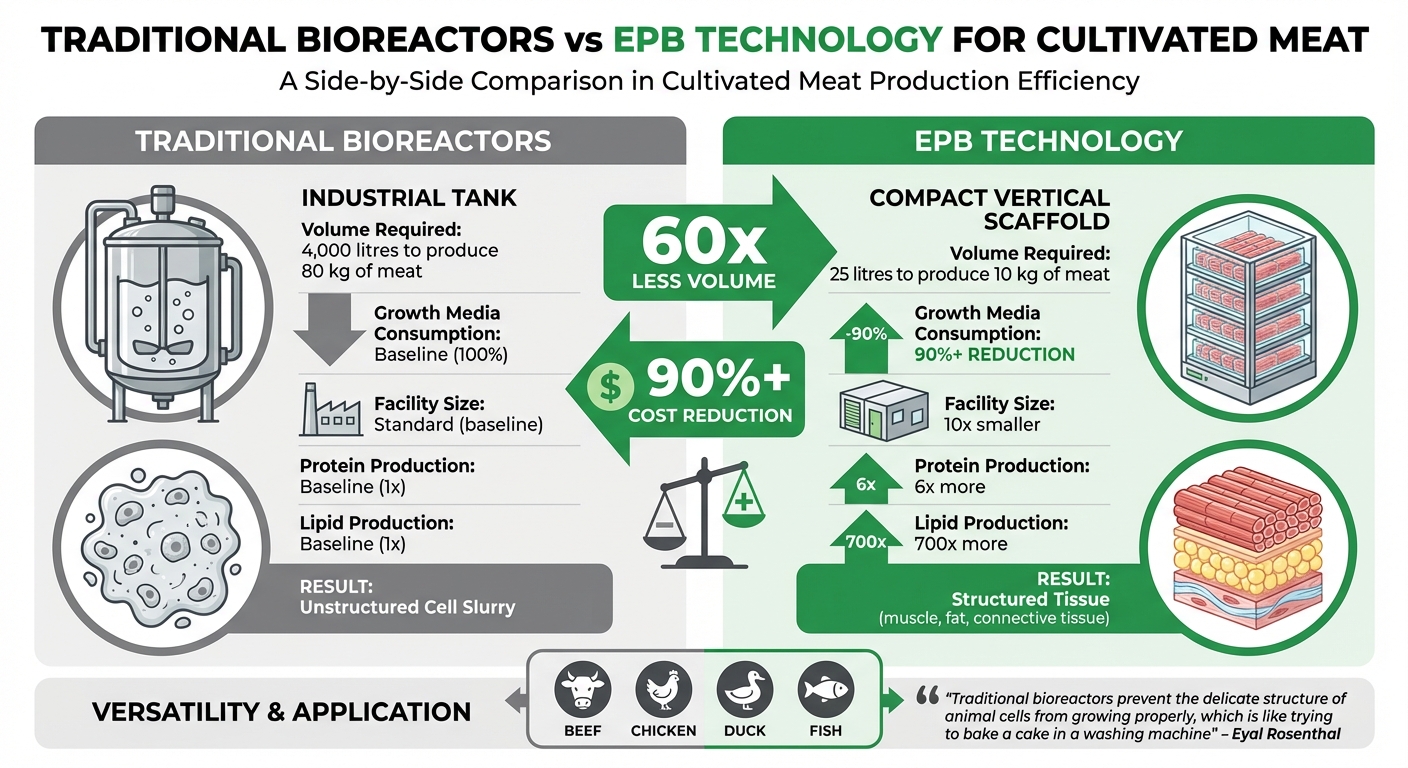

EPB Technology vs Traditional Bioreactors: Cost and Efficiency Comparison

Ever After Foods has introduced a proprietary edible packed-bed (EPB) technology that transforms the way cultivated meat is produced. Unlike conventional approaches that repurpose pharmaceutical equipment for food production, EPB is specifically designed to create real meat products. It utilises plant-based, vertical scaffolds that replicate the natural environment where animal cells grow. This allows the cells to attach and develop into structured tissues, avoiding the unstructured "cell slurry" seen in other methods [2][7]. This unique design drives significant advancements in production.

The EPB technology supports the simultaneous growth of muscle, fat, and connective tissues - the essential components of traditional meat. Impressively, it has been successfully applied across various species, including beef, chicken, duck, and fish [7]. As Eyal Rosenthal aptly describes:

Traditional bioreactors prevent the delicate structure of animal cells from growing properly, which is like trying to bake a cake in a washing machine [2].

The system also delivers remarkable results in protein and lipid production, achieving up to 6 times more protein and 700 times more lipids compared to traditional methods [7]. These lipids are critical for flavour and nutritional value, while the structured tissue format ensures the final product looks and feels like real meat, rather than a processed paste.

How EPB Technology Improves Production

The biological and engineering breakthroughs of EPB technology lead to exceptional production efficiency. For example, while conventional stirred-tank bioreactors require 4,000 litres to produce 80 kg of meat, a 25-litre EPB system can produce 10 kg - marking a 60-fold reduction in volume requirements [2][7].

This smaller scale directly translates into lower costs. The EPB system reduces growth media consumption by over 90%, a critical improvement given that growth media is the most expensive component in cultivated meat production [2][7]. Additionally, the technology uses food-grade equipment instead of costly pharmaceutical-grade alternatives and requires far less facility space. These factors combined enable significant cost reductions [1][5]. The EPB system also boosts productivity by 700% compared to other cultivated meat platforms [9], making large-scale production feasible in facilities that are 10 times smaller than current industry norms [1].

Key Benefits of the Bühler and Ever After Foods Collaboration

The collaboration between Bühler and Ever After Foods delivers three major breakthroughs: cutting costs, enabling global expansion, and addressing environmental challenges. These aren't just lofty goals - they're practical solutions tackling the biggest hurdles in cultivated meat production today.

How the Partnership Cuts Costs

One of the most significant barriers in cultivated meat production is the cost of growth media. This partnership slashes media consumption by over 90% [2], directly addressing this issue and making production more efficient and financially viable.

Additionally, the move from pharmaceutical-grade equipment to food-specific engineering helps eliminate unnecessary expenses. Eyal Rosenthal, CEO of Ever After Foods, explains:

The current industry approach to scaling is like trying to fill a swimming pool one glass of water at a time... You cannot take a pharma system and adapt it to food. [2]

The EPB system further reduces volume requirements by 60 times [2]. This means smaller bioreactors, which translate to lower capital costs, less facility space, and decreased operational expenses. Altogether, the partnership aims to cut production costs by over 90% compared to current cultivated meat technologies [8].

Bühler's Expertise in Scaling Production

With 150 years of food processing experience, Bühler is uniquely positioned to help scale cultivated meat production [10]. Ian Roberts, CTO of Bühler, highlights the potential:

We see Ever After Food holding promising technology that could drastically reduce the unit cost of producing cultured food in the future. [8]

Bühler's Mercury MES system and its extensive global service network make it possible to automate and scale production efficiently. Through the Cultured Food Innovation Hub in Switzerland, Bühler also provides state-of-the-art biotech facilities to support the development and scaling process [11].

Advancing Environmental and Food Security Goals

This partnership tackles two critical global challenges: environmental sustainability and food security. With the world population projected to reach 9.7 billion by 2050, traditional livestock farming cannot sustainably meet the rising demand for protein [12].

Ian Roberts underscores the urgency of the situation:

The global food chain faces significant challenges if we are to successfully and sustainably feed our growing population. Scaling production with patented technology, Ever After Foods will help the food industry keep pace with the protein demands of a growing global population. [3][4]

The technology enables commercial production at a scale 10 times smaller than current methods, making it easier for food producers to integrate cultivated meat into existing supply chains and strengthen regional food resilience [3][13]. This approach lowers infrastructure demands while maintaining commercial viability. By making cultivated meat more affordable and accessible, the collaboration paves the way for sustainable protein to become a realistic option for everyday consumers - delivering quality without the premium price tag.

sbb-itb-c323ed3

What This Means for Consumers

The collaboration between Bühler and Ever After Foods is a major step towards making cultivated meat a realistic option for UK consumers. By addressing one of the biggest hurdles - cost - this partnership significantly improves the chances of cultivated meat appearing on supermarket shelves. With production costs slashed by over 90% [1], the technology brings this alternative protein closer to becoming part of everyday diets.

Will Cultivated Meat Be Cheaper?

As production costs continue to fall, cultivated meat is expected to become far more affordable. The key breakthrough lies in tackling the most expensive element of the process: the growth media. Using the EPB system, growth media consumption is reduced by more than 90%. Additionally, the use of smaller bioreactors lowers both capital and facility costs. These savings make it easier for producers to adopt the technology, which, in turn, can help bring prices down for consumers.

What Increased Availability Could Look Like

Lower production costs open the door to a broader market rollout. With Bühler’s extensive global manufacturing infrastructure, this technology can be distributed to food producers worldwide, including in the UK [1]. Thanks to its compact design, the system allows for commercial-scale production at about one-tenth the size of traditional technologies. This means more facilities can start producing cultivated meat without needing massive infrastructure upgrades. The platform is also versatile, capable of producing muscle and fat tissues for a range of proteins like beef, chicken, duck, and fish. This flexibility means multiple product options could hit the market simultaneously, offering consumers a variety of choices.

How It Could Fit into Daily Diets

Because cultivated meat is virtually identical to conventional meat, it can easily replace traditional options in familiar recipes. Hybrid products - combining cultivated animal cells with plant-based ingredients - are likely to serve as an approachable starting point for many consumers [15]. Produced in sterile, controlled environments without the use of antibiotics, cultivated meat also provides an added layer of food safety by reducing risks associated with foodborne illnesses [14].

When Can Consumers Expect Cultivated Meat Products?

With production hurdles being tackled, the big question now is when cultivated meat will finally land on UK shelves.

The timeline looks promising. The Food Standards Agency (FSA) initiated a two-year regulatory "sandbox" programme in March 2025, designed to speed up safety assessments. Their goal? To complete evaluations for at least two cultivated meat products by early 2027 [16][17][18]. This means we could see cultivated meat in UK supermarkets as soon as 2027.

Companies like Bühler and Ever After Foods are working hard to scale up production and bring down costs. However, without regulatory approval, their launch dates remain uncertain [6]. Meanwhile, the FSA anticipates receiving at least 15 new applications for cultivated meat products over the next two years [19][20].

"Safe innovation is at the heart of this programme. By prioritising consumer safety and making sure new foods, like CCPs, are safe, we can support growth in innovative sectors."

– Professor Robin May, Chief Scientific Advisor, FSA [18]

Interestingly, the UK has already dipped its toes into the retail space for cultivated meat - albeit for pets. In February 2025, a London-based company called Meatly launched Chick Bites, dog treats containing 4% cultivated chicken. These treats are available at the Pets at Home store in Brentford, London [18][19]. This launch not only shows that the technology works at a retail level but also serves as a crucial proof-of-concept for future consumer products.

For those eager to stay in the loop, platforms like Cultivated Meat Shop offer waitlist sign-ups and regular updates on product launches. These resources are a great way to stay prepared for the arrival of cultivated meat in the UK.

Conclusion: The Future of Cultivated Meat

Thanks to the advancements outlined earlier, Bühler and Ever After Foods have revolutionised cultivated meat production. By slashing costs by over 90% and shrinking facility sizes by tenfold, they’ve made sustainable protein more affordable and competitive with traditional meat options [1][7]. This shift from pharmaceutical-grade systems to food-grade infrastructure marks a major step forward, allowing cultivated meat to rival conventional meat in price while offering clear environmental advantages.

For consumers in the UK, these changes bring real benefits: greater variety, lower prices, and a smaller environmental impact. Plus, the ability to produce structured muscle and fat tissue ensures cultivated meat will deliver the same taste, texture, and cooking experience as the meat you’re already familiar with.

"The global food chain faces significant challenges if we are to successfully and sustainably feed our growing population. How we produce and consume protein will continue to change, and requires a transition of our protein system to deliver this."

– Ian Roberts, CTO at Bühler [1][4]

This isn’t about replacing your diet overnight. It’s about introducing a new option that supports health, sustainability, and food security goals. Whether you’re a flexitarian, cutting back on meat, or just curious about food innovation, cultivated meat offers a way to enjoy real meat while reducing your environmental impact.

These advancements don’t just change how meat is made - they give consumers the power to choose a sustainable, affordable alternative. If you’re eager to stay updated as cultivated meat becomes available in the UK, platforms like Cultivated Meat Shop provide waitlist sign-ups, product previews, and educational materials. The future of meat is closer than you might think - why not take a closer look today?

FAQs

How does Ever After Foods' EPB technology make cultivated meat more affordable for consumers?

Ever After Foods' edible packed-bed (EPB) technology is changing the game for cultivated meat production. By allowing muscle and fat cells to grow together on an edible scaffold, it removes the need for separate scaffolds, complex separation processes, and large quantities of expensive growth medium. This streamlined approach slashes production costs significantly.

The EPB system also achieves high cell densities using much smaller reactors. Instead of relying on traditional 20,000-litre bioreactors, similar output can be achieved with reactors under 2,000 litres. This reduces equipment needs and can lower costs by up to 90%. Such advancements make producing cultivated meat more efficient and scalable, edging it closer to matching the price of conventional meat.

For shoppers in the UK, this could mean cultivated meat might soon be available at prices comparable to premium cuts of traditional meat. This makes it an appealing and more sustainable option. To learn more about this emerging category, check out the Cultivated Meat Shop, where you can find product previews, health insights, and updates on availability.

How does switching to cultivated meat benefit the environment?

Switching to cultivated meat comes with some impressive environmental perks. For starters, it can slash greenhouse gas emissions by up to 92% compared to traditional livestock farming, making it a strong ally in the fight against climate change. It also takes up much less land - especially important when you consider that raising animals for food currently uses about two-thirds of the world's agricultural land. By cutting down on deforestation and protecting biodiversity, cultivated meat contributes to healthier and more balanced ecosystems.

Water use is another area where cultivated meat shines. It avoids the heavy irrigation needed to grow feed for livestock, which means less strain on freshwater supplies. On top of that, it helps maintain soil health, reduces nutrient runoff, and keeps vital water resources cleaner. Without the environmental toll of large-scale animal agriculture, this alternative could be a game-changer for sustainable food production in the UK.

If you're interested in how cultivated meat could play a role in a greener diet, the Cultivated Meat Shop is a great place to start. They offer plenty of resources to help you learn more about this innovative option.

When will cultivated meat be available in UK supermarkets?

As of 18 December 2025, major players like Bühler and Ever After Foods are actively working to expand the production of cultivated meat, aiming to make it both more affordable and widely available. Despite these efforts, there’s no confirmed date yet for when this product will hit UK supermarket shelves.

This collaboration focuses on overcoming production hurdles, bringing cultivated meat one step closer to becoming a staple in our shopping baskets. It’s a move that could reshape how we think about food and sustainability in the years to come.